Laser technology has permeated every facet of modern life, from entertainment and medicine to manufacturing and communication. However, one of the most impressive and practical applications of lasers lies in the realm of advanced laser cutting service. To get more valuable insight about laser cutting, read the following article.

Precision beyond measure:

The first enchantment of advanced laser cutting lies in its unrivaled precision. With laser beams as thin as a human hair, it’s possible to achieve cuts with a degree of accuracy that is nearly unparalleled. This level of precision allows for intricate and complex designs that were once inconceivable, making it a favorite choice for industries like aerospace and jewelry.

Versatility across materials:

Another mystical aspect of advanced laser cutting is its ability to work its magic across a vast spectrum of materials. From metals and plastics to wood and textiles, lasers can effortlessly cut through a wide range of substances with ease. It’s like having a versatile wizard’s tool in the manufacturing world.

Non-contact sorcery:

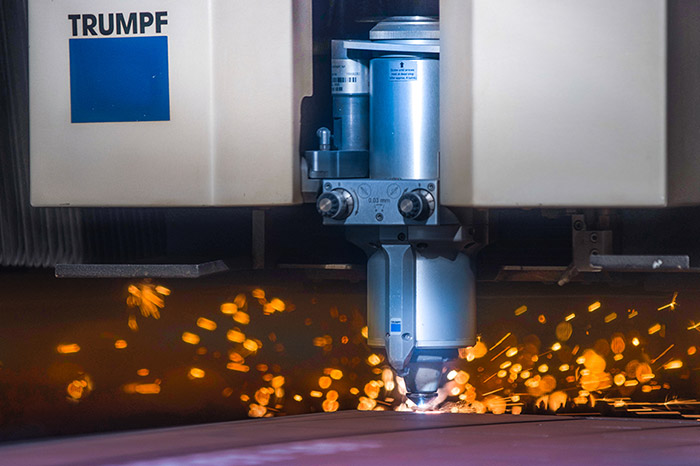

Traditional cutting methods involve physical contact with the material, which can lead to wear and tear on the cutting tools. In contrast, advanced laser cutting is a non-contact process. The laser beam hovers above the material, cutting with focused light energy. This non-contact sorcery results in cleaner, smoother edges and reduced wear and tear on the equipment.

Digital wizardry:

The secret to laser cutting’s precision and versatility lies in its digital nature. Using computer-aided design (CAD) software, intricate designs can be translated into precise cutting instructions. This digital wizardry means that you can easily switch between designs, make adjustments on the fly, and achieve consistent and repeatable results with ease.

Engraving and etching spells:

Laser cutting isn’t limited to just cutting. It also has the enchanting ability to engrave and etch. This means you can add detailed and intricate designs or markings to materials. Whether it’s personalizing a gift or branding products, laser engraving adds a touch of magic to items.

Automation alchemy:

Many advanced laser cutting systems are automated, with robotic arms and sophisticated software, allowing for continuous, uninterrupted cutting. This automation alchemy ensures consistent results and speeds up the production process, making it a cost-effective choice for large-scale manufacturing.